With 23+ years of service experience, a global supplier of professional glass processing machinery.

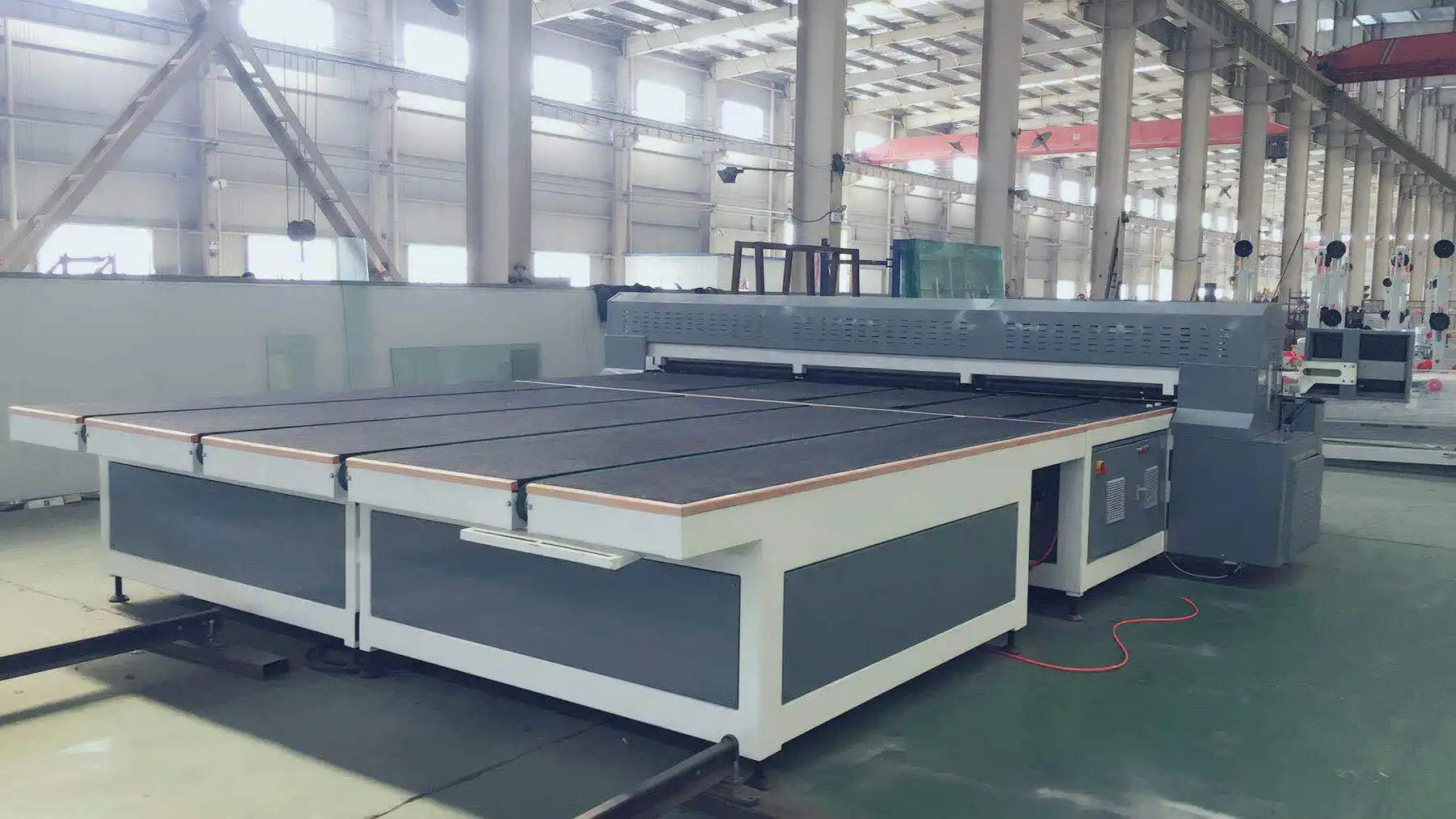

Full Automatic Laminated Glass Cutting Line

1. Max. Cutting length: 3700mm

2. Min. Cutting length: 250mm

3. Glass Thickness: 3+3~8+8mm

4. The film thickness of laminated glass: 0.38mm--1.52mm

5. Cutting Speed: 100m/min

6. Glass positioning: mechanical positioning&photoelectric positioning

7. Dimensions: Approx 7000*5100*1450(mm)

8. Weight: 4000KG

9. Work table height: 900士50mm

10. Totalpower: 15kw

11. Min. pressure:0.8MPa

Product Information

Man-machine interface HMI setting system parameters such as glass width, length, under knife pressure, etc.一一mechanical placement of glass into the synchronous belt area of the cutting table一一Automatic transmission and positioning of glass according to the cut size of input(There's a location system)一一Knife head at zero一一Pneumatic lower knife, upper and lower knife wheel cut(There's an automatic injection system)一一Cut and lift一一The upper press starts the press, and the lower surface glass breaks open一一Under the top rod up the glass, the upper surface of the glass break open一一Heat bar, start heating一一The vacuum suction cup absorbs the glass on both sides of the tangent line and pulls the cutting seam apart一一Cutting film(PVB or EVA)一一The cutting action is complete and the entire artifact is transferred to the next segment tangent position(If you need to turn around and cut, you need to do it manually)一一Whole cutting is complete.一一Manually move the processed glass to the lower slide flip bracket with the air float assembly.

Specification Drawing

Advantage

APPLICATION

SANKEN automatic laminated glass cutting machine is specially for cutting straight-line EVA and PVB laminated glass. The equipment has the characteristics of high stability, high safety, high precision and simple operation. The key positions are annealed and milled to ensure the overall stability and strength of the equipment. From the laminated glass conveying, positioning, upper and lower cutting, glass breaking, film heating, breaked glass pulling to the film cutting off, all processes are fully automated.

FAQ

70% BALANCE SHALL BE PAID OFF BY T/T BEFORE SHIPMENT.

Contact Us

Contact: Dalia Qiu

Tel: +86 15994813914

Email: sales@sankenglass.com

WhatsApp: +86 15994813914

ADD: No.2, Xinghai Road, Lanhe, Nansha District, Guangzhou City, China. P.C 511480